What Is Permeation?

- wiphaweetnvbow

- May 31, 2025

- 2 min read

Updated: Jun 2, 2025

Source: AMETEK MOCON Website - Knowledge

Permeation is the process by which gases or vapors pass through a semi-permeable material such as plastic film, finished package, medical device, or even flexible electronics. This movement happens when there is a difference in gas concentration between the two sides—typically from high to low concentration.

Many modern packaging materials are not completely gas-tight. Materials such as paperboard, rigid plastics like HDPE or PET, flexible films like LDPE or LLDPE, and metalized films using aluminum are all semi-permeable. As a result, it becomes important to measure how quickly gases like oxygen or water vapor pass through these materials. This information helps manufacturers predict how long a package can protect its contents before the product starts to degrade.

Why Is Permeation Important?

In the food and beverage industry, the gas permeability of packaging materials directly affects the shelf life and quality of the product. In electronics manufacturing, especially for items like OLED panels or solar cells, the rate at which water vapor passes through packaging materials can determine the functional lifespan of the device.

To ensure optimal product protection and shelf life, it is critical to understand gas permeation through both individual materials and complete packaging. This helps in selecting the right packaging structure for specific applications.

The most common way to report permeation is through transmission rate (TR). Permeation testers measure:

Oxygen Transmission Rate (OTR) in cc/m².day

Water Vapor Transmission Rate (WVTR) in g/m².day

Carbon Dioxide Transmission Rate (CO2TR) in cc/m².day

For full packages, the units are usually expressed as cc/package.day or g/package.day. These numbers indicate how much gas will penetrate a single package each day.

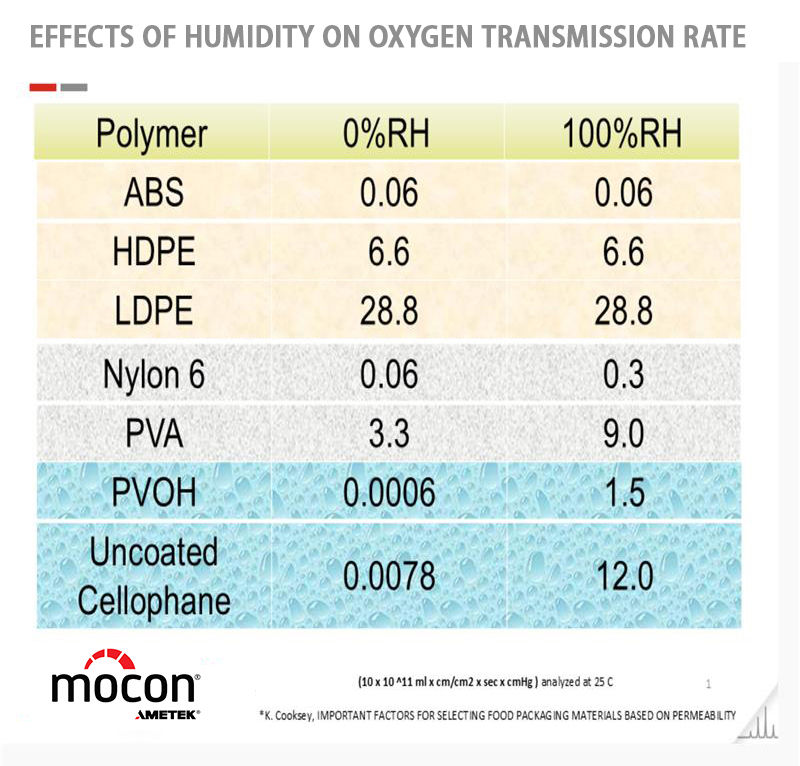

Factors That Affect Permeation:

Temperature

Relative Humidity (RH)

Thickness and structure of the material

Gas concentration difference inside vs. outside the package

Testing under controlled conditions ensures accurate and reliable results.

Why Does Permeation Matter?

Understanding permeation is key for anyone involved in packaging. With permeation data, you can:

Predict how long carbonated drinks will stay fizzy

Estimate how long a modified atmosphere will remain stable inside a sealed package

Verify whether a new packaging design meets performance goals

Ensure quality control across supply chain stages, from raw film materials to finished goods.