Frequently Asked Questions on Permeation

- wiphaweetnvbow

- May 30, 2025

- 2 min read

Updated: Jun 2, 2025

Source: AMETEK MOCON Website - Knowledge

1. What Is Permeation?

Permeation is the movement of gases or vapors through a barrier material, such as a bottle wall or film layer. It occurs naturally, moving from areas of higher concentration to areas of lower concentration.

Example: In a freshly filled bottle of carbonated soft drink, the CO₂ concentration inside (~4 atm) is much higher than the CO₂ in the surrounding air (<0.5%). Over time, CO₂ permeates out, while oxygen from the air moves into the bottle. This change leads to product degradation, such as a “flat” taste.

Permeation Occurs in 3 Steps (Solution-Diffusion Mechanism):

Molecules are absorbed into the high-concentration surface

Molecules diffuse through the material

Molecules desorb on the low-concentration side

Permeation is influenced by:

Solubility (S): How well the gas dissolves in the material

Diffusivity (D): How easily the gas moves through the material

Key Equation:

Permeability (P) = Diffusion Coefficient (D) × Solubility Coefficient (S)

In practice, Transmission Rate (TR) is used to report the amount of gas that passes through a material:

OTR (Oxygen): cc/m².day

WVTR (Water Vapor): g/m².day

CO₂TR (Carbon Dioxide): cc/m².day

2. How Is Permeation Measured?

Permeation is measured using transmission rate tests under controlled conditions. A common setup (Iso-static method) places test gas on one side of a film and a carrier gas (usually nitrogen) on the other. The permeated gas is carried to a sensor for analysis.

Common Instruments:

OX-TRAN® 2/22 – Measures OTR using Coulometric sensors

AQUATRAN® 3/34 – Measures WVTR

PERMATRAN-C® – Measures CO₂TR

3. What Factors Influence Permeation?

Environmental factors:

Temperature: Every 10°C increase doubles transmission rate

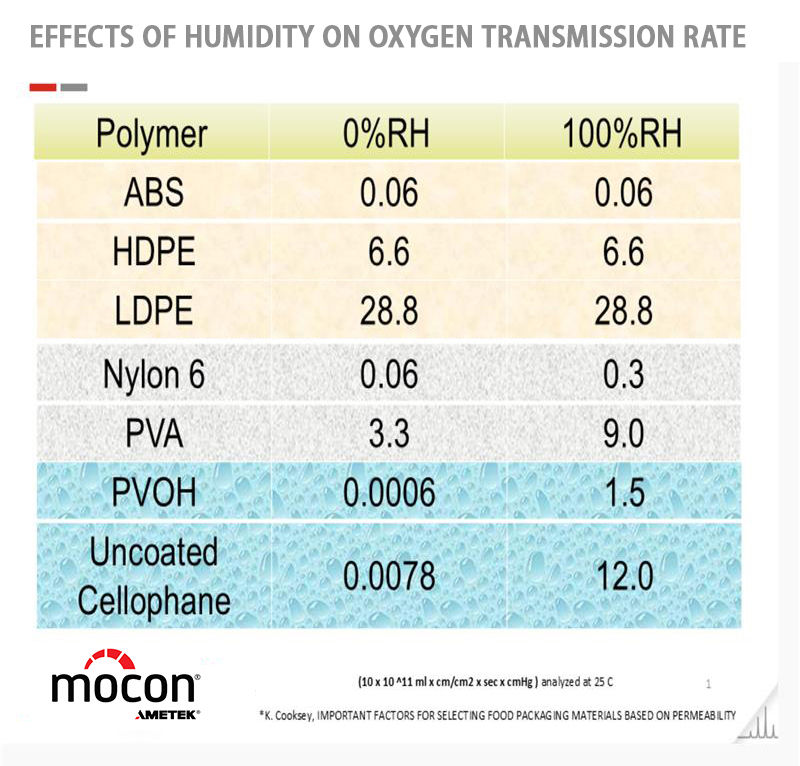

Relative Humidity (RH): Affects hydrophilic materials (e.g., EVOH)

Driving Force: Higher pressure difference increases permeation

Material Thickness: Thinner materials = faster permeation

Material properties:

Polymer chain structure and crystallinity

Moisture interaction and polarity

Surface characteristics and additives

4. ASTM D3985 vs F2622: Which OTR Method Should You Use?

Oxygen barrier packaging is essential for oxygen-sensitive products. Accurate OTR testing ensures proper material selection and quality assurance.

Two ASTM Methods:

D3985: Uses Coulometric sensor (no calibration needed)

F2622: Uses non-Coulometric sensors (requires calibration)

Comparison Table:

Feature | Coulometric (D3985) | Non-Coulometric (F2622) |

Sensor calibration needed | No | Yes |

Carrier gas dependency | No | Yes |

Sensor response linearity | Linear | Not linear |

Best for | High-barrier films | Medium/low barrier films |

Sensor cost | Higher | Lower |

NIST traceable | Yes | No |

Recommendation:

High-barrier materials (e.g., for sensitive foods): Use Coulometric method for higher accuracy and reliability

Low-barrier materials (e.g., fruit packaging): Non-Coulometric method is suitable

5. Should I Test OTR with Specific Relative Humidity (RH)?

Yes, depending on the type of polymer.

Fickian Materials (e.g., polyolefins): Hydrophobic, OTR results are consistent regardless of RH

Non-Fickian Materials (e.g., EVOH): Hydrophilic, RH affects polymer structure and permeability