Don’t Let Moisture Skew Your Permeation Testing Results

- wiphaweetnvbow

- May 14, 2025

- 2 min read

Updated: Jun 2, 2025

Why Humidity Control Is Critical for Accurate Barrier Measurements

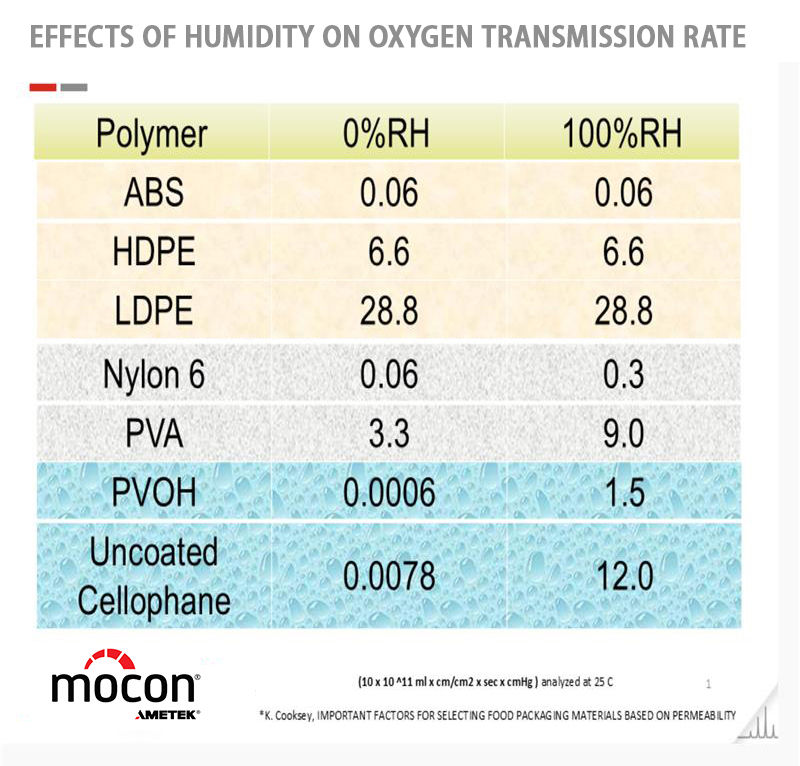

Permeation testing can yield misleading results when dealing with moisture-sensitive materials. That’s because a material’s barrier performance can vary significantly depending on the type of permeant and the surrounding humidity. A film that provides excellent oxygen barrier protection may offer poor resistance to water vapor, and vice versa. For this reason, multi-layer films are often used in packaging—each layer is designed to block a specific gas or vapor.

Moisture Sensitivity Example: Nylon

Nylon is a prime example of a material highly sensitive to moisture. Its oxygen transmission rate (OTR) and water vapor transmission rate (WVTR) can show large variations depending on how the test is conducted. In particular, WVTR values for nylon films can differ significantly depending on whether the test follows ASTM E96 or ASTM F1249, even if the relative humidity (RH) gradient is the same (e.g., 50%).

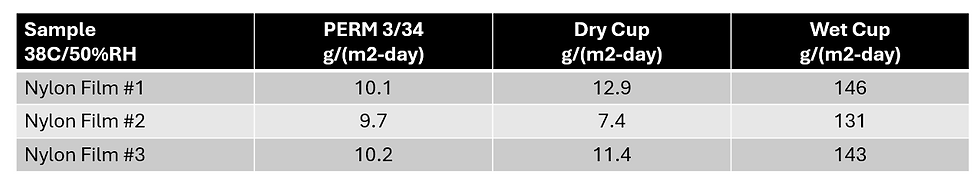

The key difference lies in the testing method—ASTM E96 can use either a dry cup or wet cup setup, while ASTM F1249 uses a dynamic, instrument-based approach. These differences can lead to inconsistent or non-comparable results, especially for materials affected by RH levels (see Table 1).

Why Precise Humidity and Temperature Control Matters

Achieving accurate and repeatable permeation measurements requires tight control of both humidity and temperature. This involves:

High-precision relative humidity probes

Continuous temperature regulation and monitoring

Temperature plays the most critical role in permeation behavior, as described by the Arrhenius equation. But RH is also temperature-dependent, so both parameters must be controlled in tandem to ensure reliable data.

Choose the Right Test for Real-World Accuracy

Once you understand how your material interacts with moisture, it’s essential to select the appropriate testing method. A method that works well for one permeant may not be suitable for another. Choosing the correct standard—and maintaining strict environmental controls—ensures your data reflects the true barrier performance of your material in real-world applications.